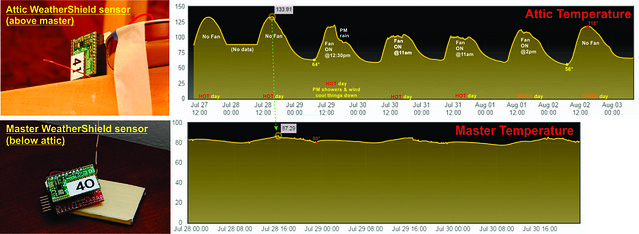

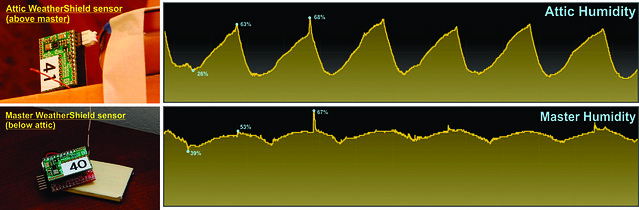

Now that WeatherShield is available to take high accuracy temperature, humidity and pressure measurements, it’s time to spread it around the property and watch the trends. I’ve already posted an example of upgrading my mailbox notifier project to include the WeatherShield. In this post I want to show my GarageMote upgrade to add a WeatherShield (WS), this was another quick evening project for today.

The garage is an interesting place to measure that data since it sits in between the house and the bitter winter cold or torrid hot summer. Would have been nice to have this data when I insulated my garage doors to see how effective that was.

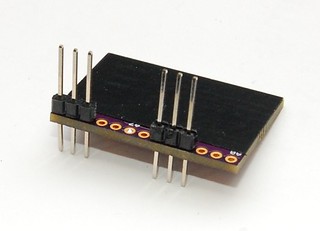

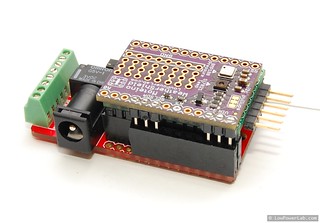

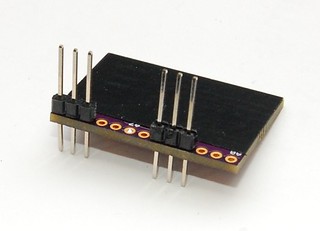

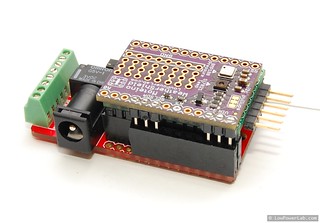

The new GarageMote R2 includes an extra row of pins that are linked to the Moteino top header, which can be used for any general purpose, add more stuff to your GarageMote. This is perfect since WS‘s relevant pins are all on that same side. I had a prototype WS that I chose to stack on top of the Moteino, so male headers get soldered below, but you could also flip it over and have it be side by side the Moteino with headers on top. I shield the bottom of the WS with electrical tape, and soldered a pair of long pin headers with the longer side on the bottom of the WS.

|  |

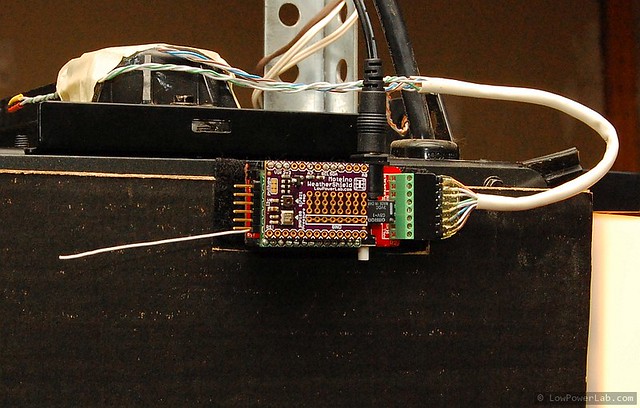

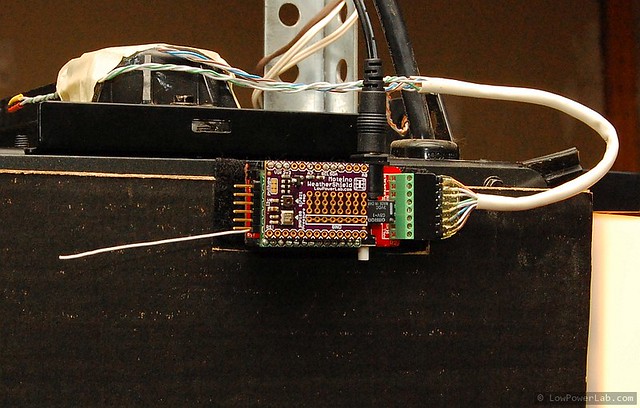

This allows stacking of the WS on top of the Moteino using the female header that I soldered to the empty side header on GarageMote, the extra length headers are clipped off the top of the WS. I then install it back onto the door opener as before. GarageMote is permanently powered so it can afford to leave the transceiver in RX mode which is also necessary to listen for commands from a browser or mobile device (OPEN, CLOSE etc). That means it can also listen for wireless programming tokens, in fact the GarageMote sketch was always programmed that way so if a firmware change is needed it wouldn’t need to be disconnected, but instead reprogrammed wirelessly. The new revision of the GarageMote sketch is updated to include the WS code for periodic reading/reporting of the sensors data (which is excluded by default, and can be enabled by uncommenting the #define WEATHERSHIELD directive).

The resulting data arriving on the gateway looks like this:

F:4397 H:41 P:29.42

where F is fahrenheit degrees in hundreds (divide by 100), H is humidity in % and P is atmospheric pressure in inHg. The data is reported every 5 minutes, enough to get a pretty good resolution in a place that doesn’t expect large sudden fluctuations. Graphing and logging will be added later when I enhance the Gateway stack. For now this just serves as a quick demo and example of how WeatherShield can be used. Enjoy!